Calibration of instruments and standards enhances the efficiency & capacity of production which will help to reduce the errors & effect of the depreciation of Instruments on the production line.

As defined by FDA regulations, “Calibration is basically comparing the measurements made by a device against a reference instrument or standard to check its precision, accuracy and limits.”

Role of Calibration in Life Science Industry

Calibration is immensely important process in life science industry to finetune the instrument’s life over the time. Calibration can be depending on the following factors:

- Induction of instruments

- Planned/regular interval calibration

- Changes to the environmental conditions like temperature, humidity etc.

- Requalification of instruments

- Inaccurate instrument readings

- Frequent mismatches in the instrument & standards readings

- Frequent deviations/errors with the instruments

- Frequency of use of instrument in production

- Poor quality of production

- Instrument performance history trend analysis

- Uncertainty calculation results

Different Applications of Maximo Life Science for Calibration

Applications used to define/configure calibration in Maximo life sciences are:

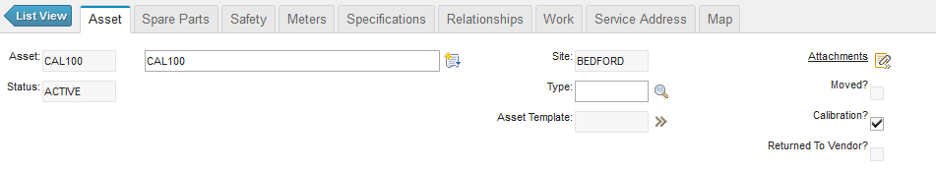

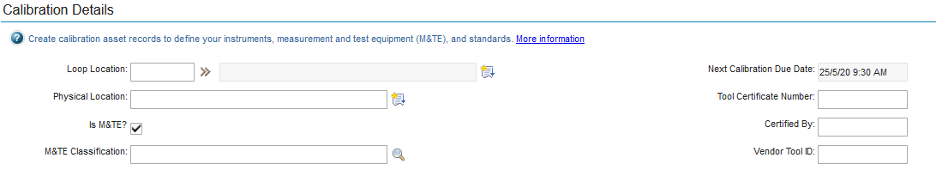

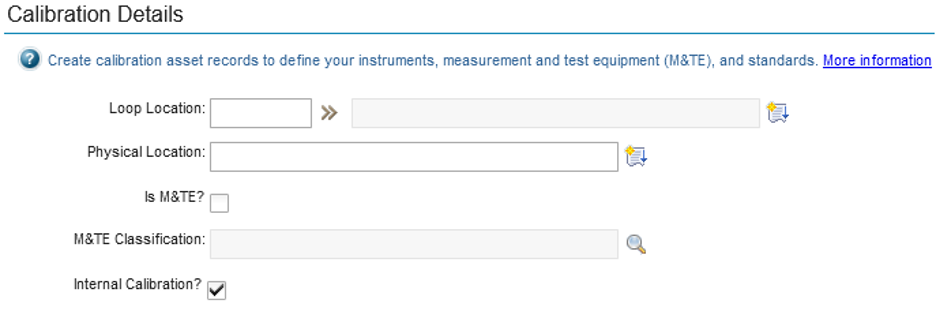

1.Asset application: It manages equipment, instruments & masters/standards in Maximo. Calibration checkbox on an asset indicates that it is a calibration asset.

Is M&TE checkbox along with Calibration checkbox indicates that it is a Calibration Master/Standard (Tool).

Asset application can track specifications like Full Range, Operating Range, Accuracy, Resolution, Least count, Make, Model & Capacity etc. of an equipment, instrument & masters/standards.

Calibration Equipment or Standards can be categorized as internally calibrated or externally calibrated. Internal calibration flag on asset indicates that instrument or standard is calibrated with in the premises.

2.Tools Application: This can be used to configure a tool as “Is M&TE” & “Rotating”. The tool can be associated with an asset to classify it as Measuring & Test Equipment calibration standard.

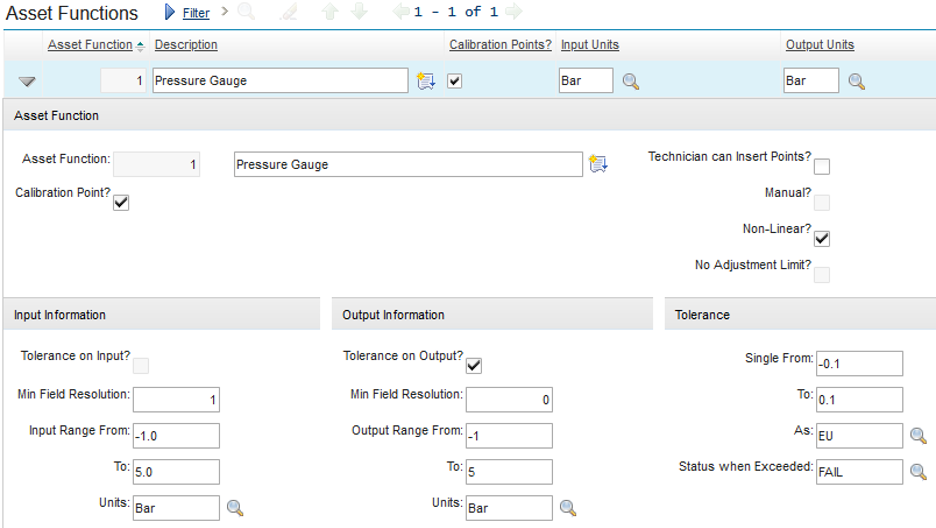

3.Data Sheet Template Application:

- Data sheet templates are pre-defined templates which are used to calibrate instruments or masters.

- It comprises of asset function and calibration points.

- Calibration points are used to setup set points for UUC/master readings.

- Asset function is used to categorize data sheet template as Linear (Dynamic Calibration Points), Non-Linear (Static Calibration Points) & Manual.

- Asset function is used to manage calibration data such as Input & Output ranges, Acceptance Criteria/Tolerances & Uncertainty Measurements.

4.Job Plan application: It can be used to associate calibration asset with data sheet template.

5.Preventive Maintenance application:

- Preventive maintenance application can be used to plan fixed/floating schedule with frequency and tolerance window for instruments or standards

- Due dates for Fixed schedules to be decided based on calibration work order’s target dates.

- Due dates for Floating schedule to be to be decided based on calibration work order’s actual finish date.

6.Work Order Tracking Application: It can be used to create and manage calibration work orders for instruments or standards with following major components-

- Data sheet templates can be associated to calibration work order

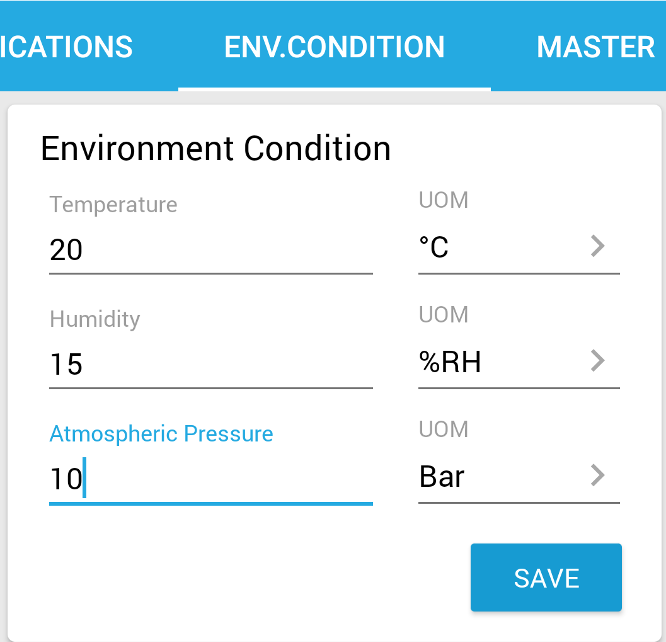

- Environmental conditions- Temperature, Humidity & Atmospheric Pressure can be captured on calibration work order

- As-Found & As-Left readings can be recorded in the associated data sheet. As-Left readings can be captured if As-Found readings are outside tolerance limit

- System decides the calibration test result as Pass/Fail on calibration work order based on the As-Found & As-Left readings

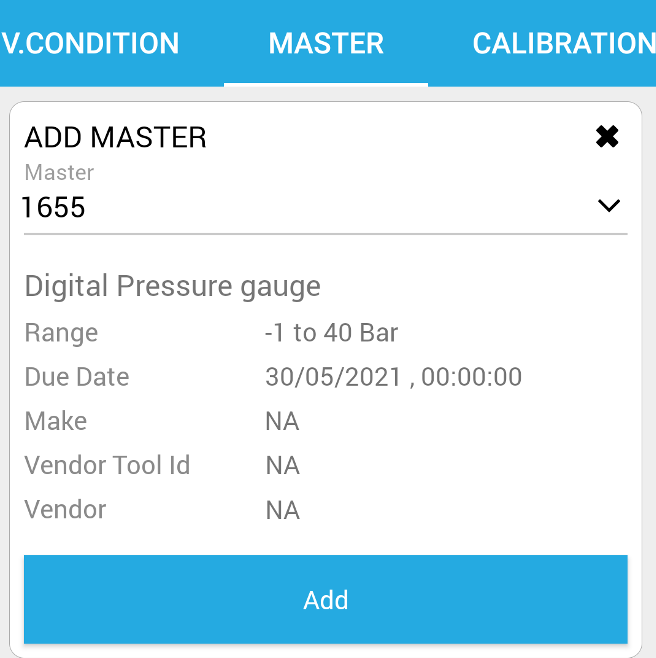

- Masters/Standards can be captured on calibration work order

- External Calibration certificates can be attached on calibration work order

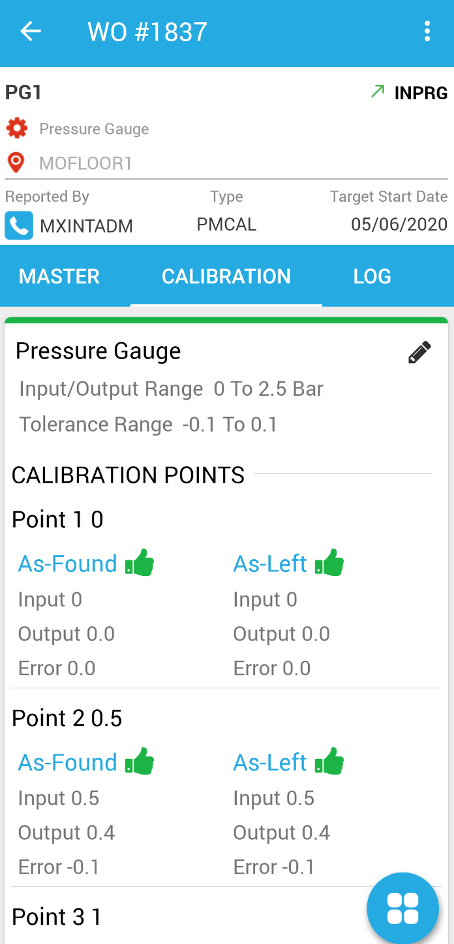

Calibration on Mobile (EAM360 app)

EAM360 application can be leveraged to record calibration readings on Mobile devices in a hassle-free way.

Tabs used for calibration are- Calibration, Master and Environment Condition etc.

- Calibration Tab: The tab can be used to record As-Found & As-Left readings which in return will display calibration test result as Pass/Fail.

- Environment Condition Tab: The tab can be used to record environment conditions such as Temperature, Humidity & Atmospheric Pressure.

- Master Tab: The tab can be used to capture the Master used for calibration.

Author:

Shama Seth

Lead Consultant