Mean Time between Failures (MTBF) & Mean Time Taken to Repair (MTTR) are the key metrics used widely across industries to measure Asset performance. Organizations strive to achieve higher MTBF and lower MTTR and these two metrics are important Key Performance Indicators (KPI) of Asset intensive industries.

While calculating MTTR (Total Breakdown Hours / No of Breakdowns) is relatively straightforward, MTBF calculation is interpreted differently by Production and Maintenance functions. This article explains how Production & Maintenance MTBFs are calculated and its insights.

Definition of MTBF

MTBF is the average hours that an Asset can operate without a failure. The Plant or Factory or Unit MTBF can be derived based on the average of all its constituent Asset MTBFs. It is generally used to quantify how reliable the Assets are for productive use.

Maintenance MTBF (Downtime Based MTBF)

The following formulae is used to calculate Downtime based MTBF:

Planned Production Hours

It’s the number of hours that an Asset was planned for production and not the running hours of an Asset.

If it’s a continuous process industry such as Petrochemical or Refinery, where the Assets are planned to run 24 x 7 hours basis, Planned Production Hours can be computed based on the calendar hours minus planned shutdown hours.

If it’s a discrete industry such as Automobile or Household Appliances manufacturing, where the Assets are planned to run only 16 hours (in two shifts), Planned Production Hours can be total planned hours minus planned shutdown hours. The planned hours can be derived from the Production plan.

In Maximo, the Assets can be associated with a continuous Meter called ‘Planned Production Hour' and can be updated daily or weekly or monthly basis (the frequency is based on how an organization wants to monitor the MTBF Trend).

Downtime Hours

It’s the number of hours during which the Asset is not available for productive use due to break down.

In Maximo, the down time hours can be reported against the Breakdown Work Orders. Maximo can be configured to mandate downtime hours entry when a breakdown work order is created for the Asset.

Number of Breakdowns

It’s the number of Breakdown occurrences for a given period of time. In Maximo, this can be calculated based on the number of breakdown work orders created against the Asset.

Production MTBF ( Run Hours based MTBF )

The following formulae is used to calculate Run Hours based MTBF:

Total Run Hours

It’s the number of hours that an Asset was running for productive use. In Maximo, the Assets can be associated with a Continuous Meter called ‘Run Hours’ and the running hours can be updated on the daily or weekly or monthly basis ( the frequency is based on how an organization wants to monitor the MTBF Trend).

If there is an ERP / MES system which can capture the Asset Run hours, Maximo can be integrated with those systems to get the updates as Run Hour meter readings.

Number of Breakdowns

Maintenance Vs Production MTBF

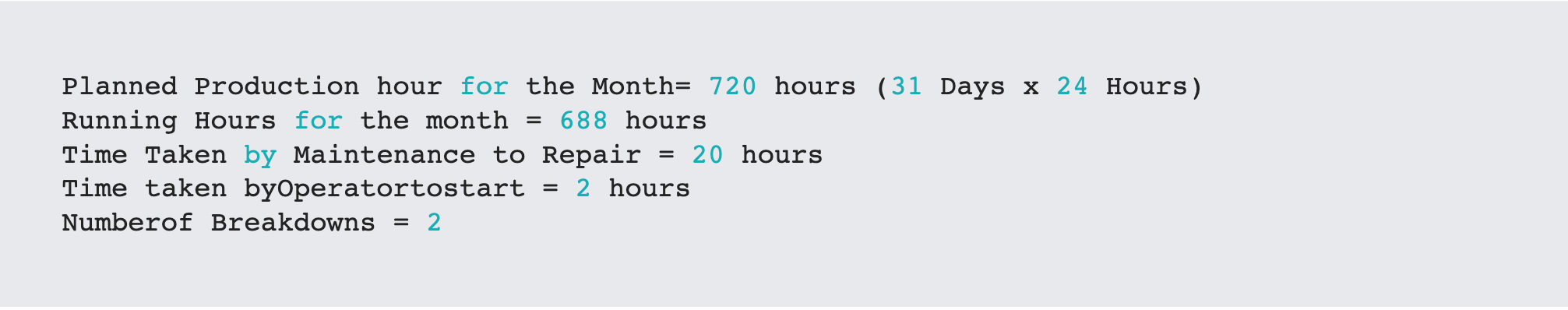

Let’s consider the following parameters of an Asset and calculate MTBF

Maintenance MTBF for the Month = (Planned Production Hours – Down Time Hours ) / Number of Breakdowns)

= (720 – 20) / 2

= 350 Hours

Production MTBF for the Month = Total Run Hours / No of Breakdowns

= 688 / 2

= 344 Hours

The hours due to production delays such as delay in starting the Asset are not factored in Maintenance MTBF, whereas it's factored in Production MTBF.

It’s not a bad idea to monitor both MTBFs. The Maintenance MTBF will help to measure the maintenance performance whereas the Production MTBF will help to measure the overall performance. Organizations can envisage measures to reduce the gap between Maintenance and Production MTBF to improve the overall performance.

Author:

Principal Solution Architect - Maximo & EAM360. Helping client with successful EAM Implementation| BlockChain & Iot Enthusiast