EAM360 Power Generation Case Study

EAM360, a next-generation native mobile application for Maximo, is implemented to optimize maintenance and material management processes for a Gas Turbine power plant managed by a leading US-based O&M service provider.

Top challenges

The plant managers and process owners were concerned about reduced wrench time due to dual reporting of the work – first in a paper form on the field and later by entering in Maximo. The technicians were not comfortable with updating the work details to the Maximo system. They realized the need for implementing the mobile solution to update work actuals directly at the worksite. The following are the key challenges faced:

- Implementing solutions for the O&M organisation as well as the power plant in different geographies.

- Remote implementation of the solution.

- Accessibility challenges from remote locations sites with poor internet connectivity.

| Industry | Power Generation |

| Specialties | Africa's leading energy solutions provider |

| Location | Nigeria |

EAM360 steps in

As a leading provider of mobile EAM products, we introduced a collection of role-based applications with various features and components to support and enhance the diverse business processes. The key solutions includes:

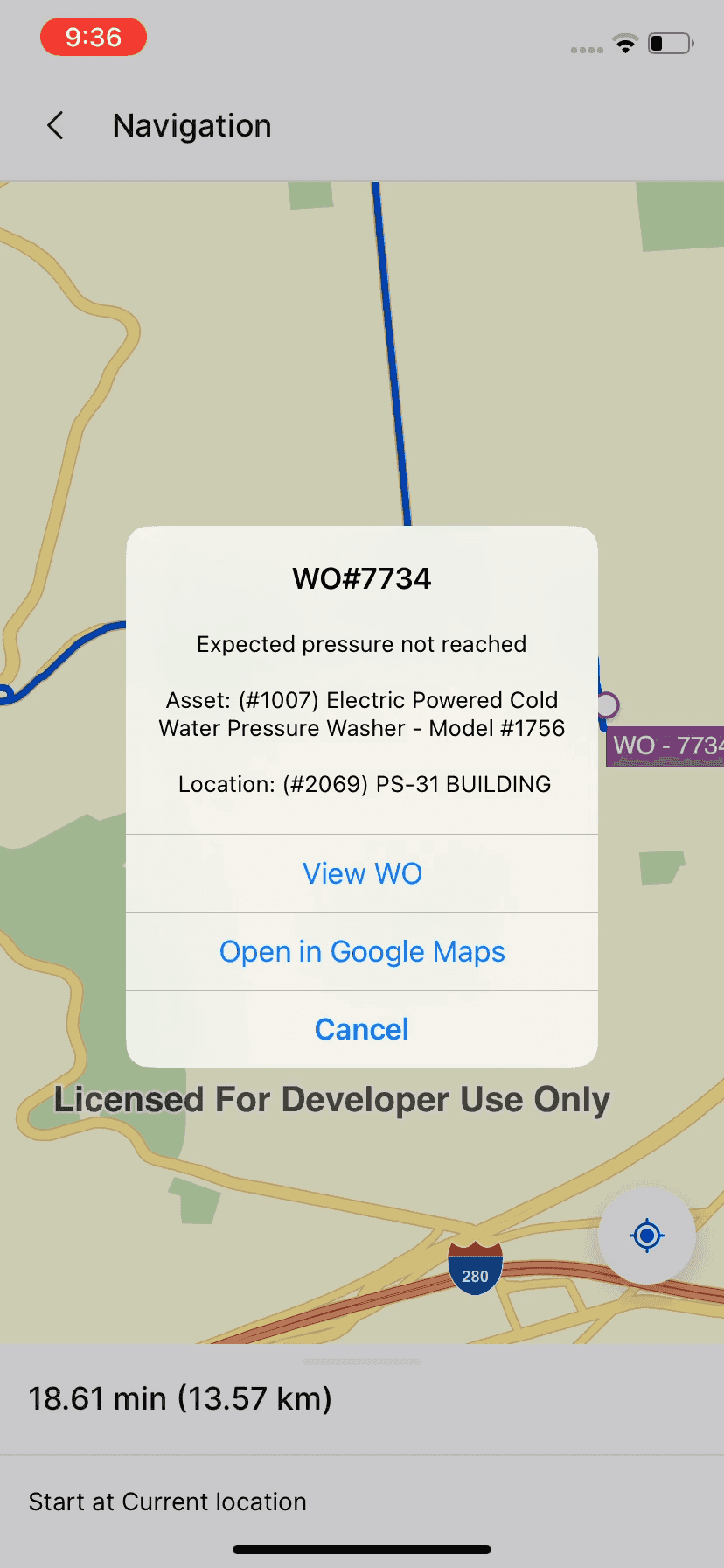

- Real time notifications for breakdown and corrective maintenance work orders for the technician on the field.

- View Safety permit requirements and receive safety alerts for work assignments, in the Mobile app.

- Update Work Actual -Material, Tools, Labor, Log with photos/videos, Failure codes & Classification/Specification attributes. The ability to record entries via Text-to-Speech was also enabled.

- Utilization of the Maximo workflows for streamlined SOPs.

- Offline access to work from locations with restrictions to use mobile phones in the online mode.

- The ability to approve Purchase Requisitions, Purchase Orders and Invoices with the click of a button was introduced for the plant managers.

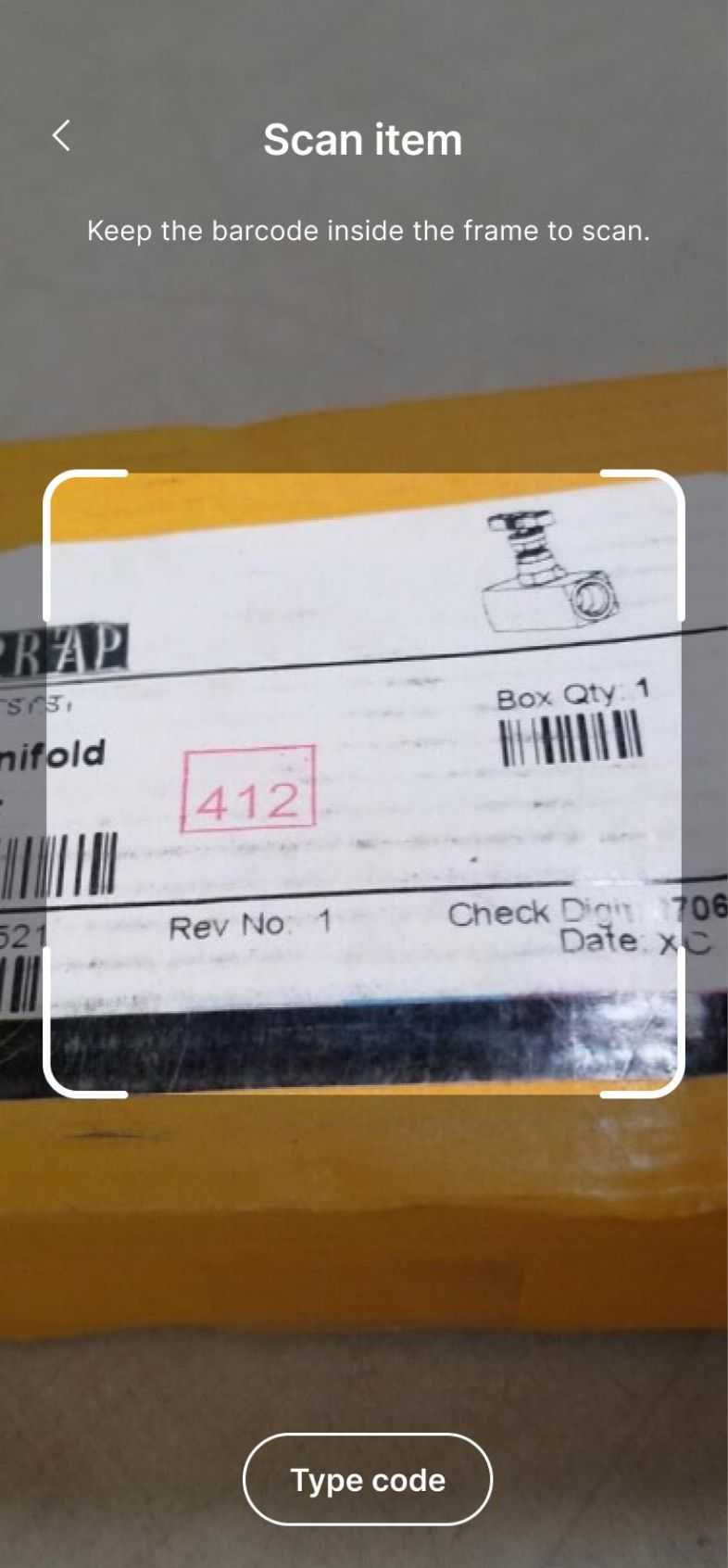

- Perform physical count, issue return & receipts, record purchase and inventory details from the Storekeeper app to optimize the Inventory.

Solution components

- IBM Maximo 7.6.0.9

- EAM360 Technician Mobile App

- EAM360 Storekeeper Mobile App

Driving impact with tangible results

Implementing a fully integrated EAM system has helped the team to handle maintenance and operation related activities effectively from the mobile app. The following are a few key benefits experienced by the client after implementing our solution:

- The suite of mobile apps supported with managing complex workflows- work order management to recording of purchase orders, all in a single interface.

- The improved data integrity helped in taking better business critical decisions.

- Improved safety mechanism along with safety permit documentation & safety alerts.

- The Offline access functionality of the application enables uninterrupted access to record work related information.

- Complete elimination of manual paperwork resulted in improved productivity and also helped to achieve a greener workspace and environment.

Enterprises across the globe engineer their assets into work, energy and systems that facilitate the lives of millions. Watch how EAM360 helps.