EAM360 Life Sciences Case Study

EAM360, a next generation Mobile application for Maximo, is implemented to optimize engineering & calibration activities for GMP & GEP critical assets in a pharma manufacturing company.

Top challenges

Implementing a Computerized Maintenance Management System (CMMS) in a pharmaceutical manufacturing environment presents unique challenges due to stringent regulatory requirements. Life sciences organizations must ensure full compliance with FDA, EMA, and other regulatory bodies, which necessitates robust system validation, data traceability, and audit readiness. The CMMS must adhere to Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) as part of Computer System Validation (CSV) to meet compliance expectations.

Beyond regulatory concerns, the maintenance team must balance compliance with operational efficiency—focusing on reducing Mean Time Between Failures (MTBF) and improving wrench time, all while maintaining meticulous records of work execution.

Some of the key challenges encountered by the team:

- Standardizing diverse calibration templates and integrating them into a digital system

- Managing the complex workflow processes with multiple level of approvals/reviews

- Minimizing human errors in calculations and ensuring data accuracy through automated input and validation

- Ensuring real-time availability of historical maintenance records to support decision-making and audits

- Visibility of up to-date pending work for the Operators and Engineers

- Capturing miscellaneous Asset events that needs to be recorded to meet the audit requirements

| Industry | Life sciences |

| Specialties | Worlds largest Vaccine Manufacturer, Biotechnology and Pharmaceuticals |

| Location | India |

EAM360 steps in

As the leading provider of EAM mobile products, we have implemented a role-based Mobile application to support and enhance the Engineering and calibration processes for the Life sciences organization. The key solutions includes:

- Contextual display of calibration forms to update Calibration readings, Environment Conditions & Masters

- Mobile notifications of workflow assignments for quicker approvals/review

- Instant display of results based on the entered calibration readings

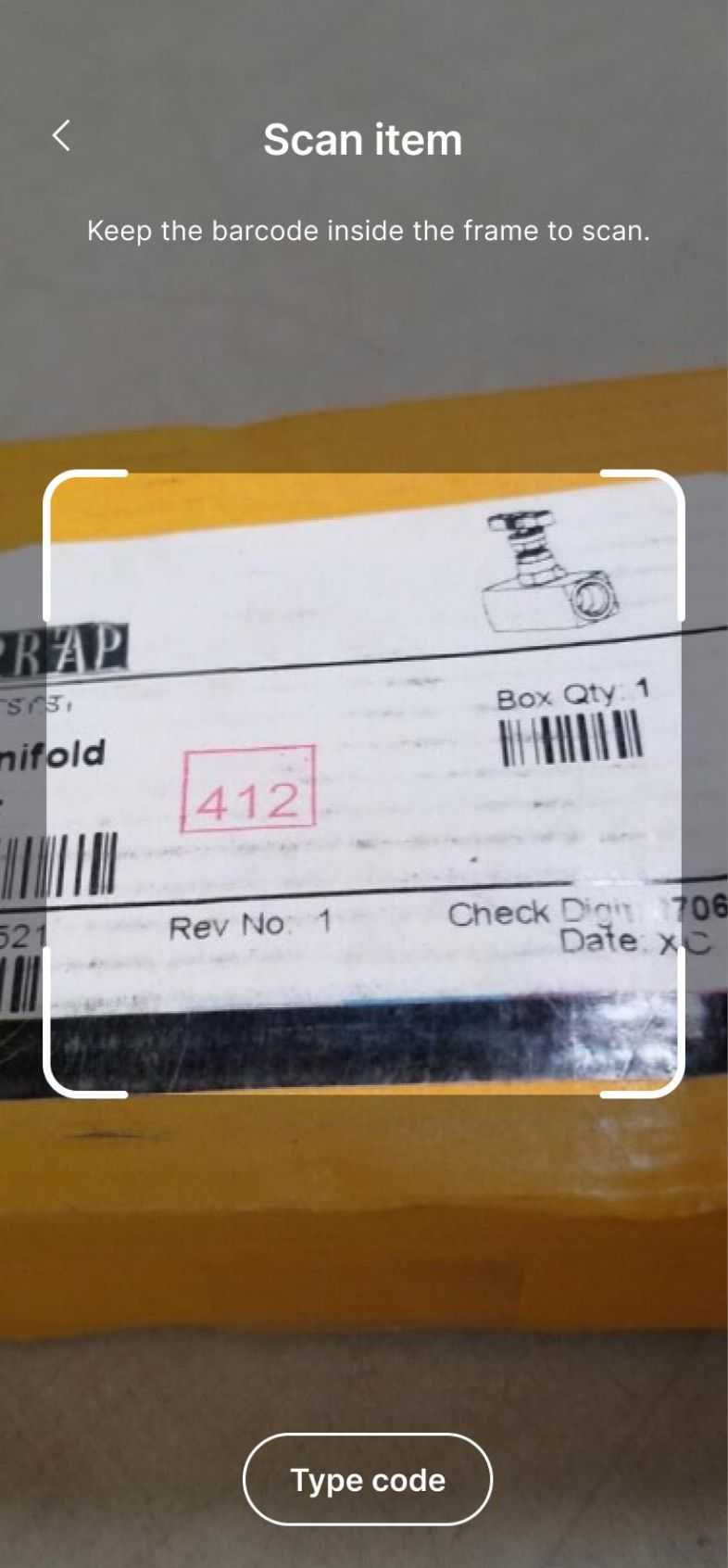

- Easy access to maintenance history with a click of a button or by scanning QR/Bar code of the Asset

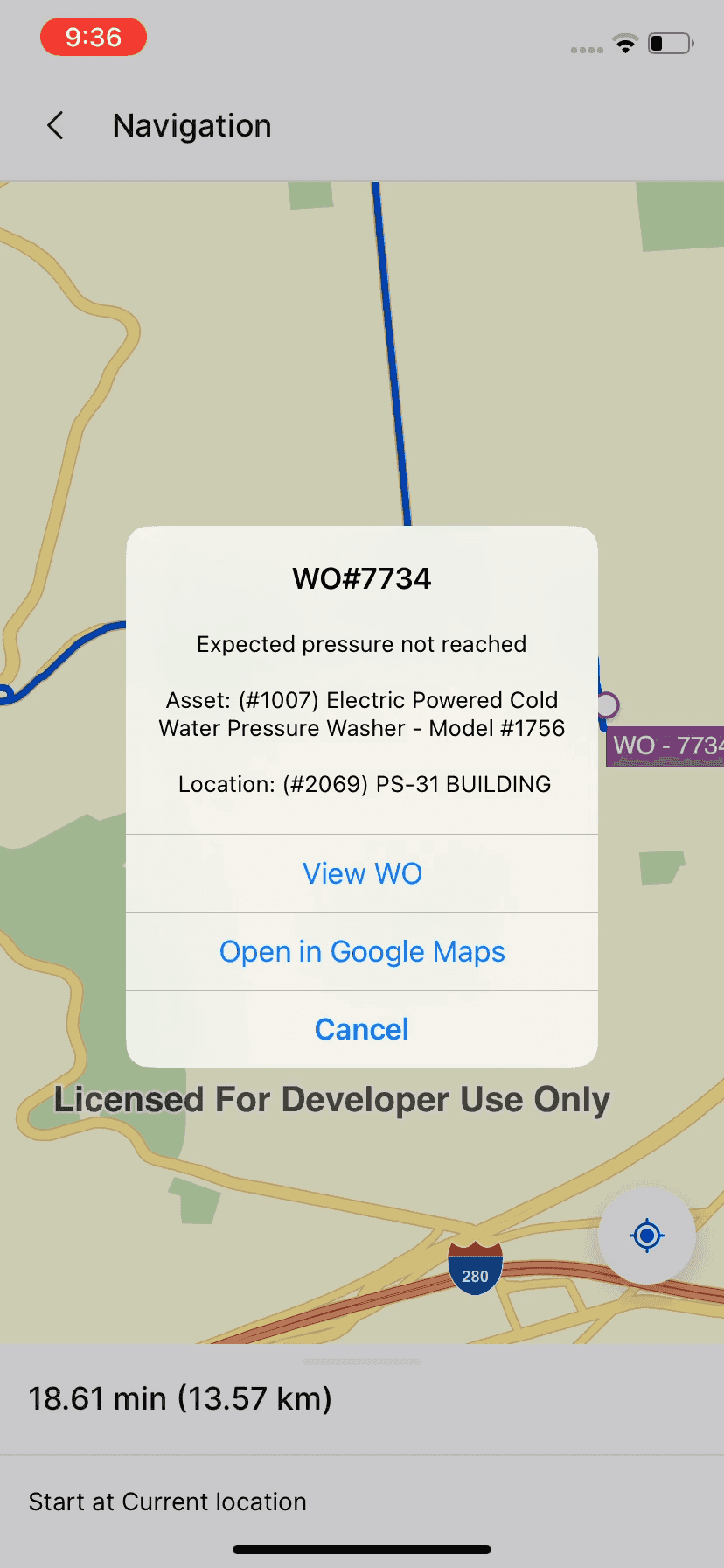

- Role based assignments for Engineering & Calibration activities

- Record Asset events on the go with a few taps

- Ability to access data & perform activities offline, in both areas with internet restrictions and remote locations with poor network coverage

Solution Components

- IBM Maximo Life sciences 7.6

- IBM Maximo Calibration 7.6.0.0

- EAM360 Technician Mobile App

Driving impact with tangible results

Implementing an enterprise wide unified EAM solution helped the team to handle maintenance and calibration related activities effectively from a mobile device on the go. The following are a few key benefits realized by the client after using our solution:

- Fully Automated processes for executing engineering activities in the facility

- Perform tasks instantly and access Asset details from virtually anywhere even without an internet connection

- Reduction in possible human errors in data entry

- Digitisation of Calibration operations improved the calibration result calculation efficiency

- Facilitation of multiple use cases of Calibration in a single platform

- Quickly assign & reassign work orders to technician across different shifts

- Compliance with 21 CFR part 11, FDA guidelines for CSV

- The complete elimination of manual paperwork helped to achieve a greener workspace/environment

Enterprises across the globe engineer their assets into work, energy and systems that facilitate the lives of millions. Watch how EAM360 helps.